For the latest in product news, visit or blog site.

Preventing Dust Explosion, Fires

Spark detection systems are used in production equipment, material handling, dust collection and pneumatic conveying systems. When working materials, sparks are created very quickly. A dull tool, a damaged fan bearing, an overheated motor, or a foreign object within the material can be the cause. This is a constant danger for all facilities where combustible materials are being worked, exhausted, transported, filtered or dried.

Detect and extinguish sparks and burning embers before they create a fire or dust explosion. The GreCon sensors detect even the smallest spark’s infrared radiation. The sensors signal the control console to initiate instantaneous countermeasures thus preventing the spark from entering the dust collector or other downstream areas. The system extinguishes sparks without stopping production. Other countermeasures can be triggered including deluge valves, diverting or abort gates, or custom PLC action. Call 503-641-7731; visit grecon-us.com

Versatile Moisture System Offered

MoistureScan XT measures total moisture content of fiber using dual-microwave technology and Windows XT operating software. It can be installed behind dryers up to 284° F with 4-20mA moisture and temperature data signals available to PLC controlling dryer. It’s also used for moisture conditioning of fiber before pellet machines. MoistureScan XT system is stable, insensitive to light, dust, color of fiber, has no moving parts and is maintenance-free. It installs in hoppers, metering bins, chutes and screw conveyors. Call 503-643-6305; visit ews-usa.com

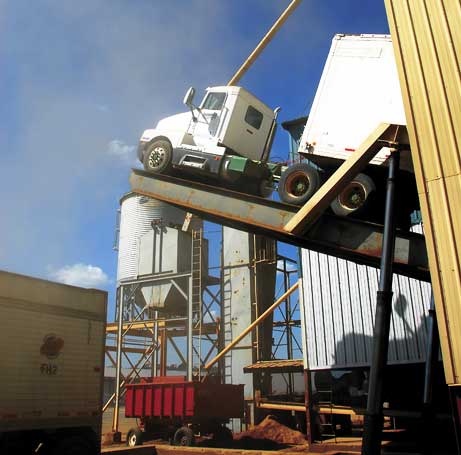

Unloading Systems Being Installed

The demand for biomass truck unloading stations remains strong for Bruks Rockwood. Most recently these systems have been employed by power generating customers looking to receive difficult wood waste materials. Typical materials include refuse from pulping operations, sawmills and urban waste.

EPCOR/Primary Energy is implementing two of these systems at its Roxboro, NC and Southport, NC power plants. Bruks Rockwood is supplying a drive-thru and back-on unit to these locations. The waste materials received will be processed and used as fuel in conjunction with other fuels such as coal and tire derived materials.

Dominion Energy is also employing two of the unloading systems at its newest clean coal power plant in Virginia City, Va. This plant will utilize fluidized combustion to produce 585 MW of clean energy. Twenty percent of the energy produced will be derived from wood waste.

Boiler Feed System Bound For S. Korea

Jeffrey Rader Corp. was awarded a significant contract to supply an alternative fuel material handling and boiler feed system in Jeonju, South Korea. The system will be part of a 100 MW cogeneration plant that will supply power and process steam for a newsprint mill. Jeonju Paper Mill will replace an older coal fired boiler using a grate fired system with a bubbling fluidized bed design which is capable of firing a mixture of alternative waste fuels consisting of bark, Refuse Derived Fuel (RDF) pellets, DIP sludge and plastics rejects from the mill’s recycled fiber process.

Delivery is ongoing, and it is anticipated to be in full operation by the end of 2009. The Jeffrey Rader material handling and boiler feed system will supply more than 30 tons per hour of waste fuels to the BFB boiler. The Jeffrey Rader system uses pneumatic conveyors to transport fuel to a receiving hopper which distributes fuel into two boiler house mounted storage silos. Fuel is then reclaimed with screw reclaimers and distributed and metered into four infeed points around the boiler with a high level of reliability and accuracy. Visit jeffreyrader.com

Database Appeals To Investor

James W. Sewall Co. and Forisk Consulting, LLC offer MillVantage, an online geodatabase of information on mills and wood-consuming bioenergy facilities. Designed to meet the needs of forest resource managers, timberland investors, and forest industry and bioenergy investors, MillVantage provides geospatial data, mapping and applications for use in locating wood products facilities and assessing wood markets in specific geographic areas of interest.

MillVantage is available as an online subscription service, hosted on Sewall’s GeoPower platform, and as a fully configurable product for use with existing GIS software. Subscription service users can access data quickly and efficiently over the Web, customize queries and maps, and download map (shapefile) and database (CSV) files for reporting, using only a browser and Internet connection. Map coverage now includes 12 states in the Southeastern U.S. To access a demo site, visit geopower.jws.com/milldb; call 704-846-1450; visit forisk.com

Quick Reaction To Burning Material

The pneumatic conveying of combustible dusts carries an inherent risk for dust fires and explosions in many applications. Drying and hammermilling operations can often cause sparks, which are typically the ignition source for fires and explosions in dust collectors and air filtration equipment.

The Flamex Spark Detection and Extinguishing System is the most cost effective solution for the prevention of these baghouse fires and explosions. It can identify and extinguish a spark in a pneumatic duct within a fraction of a second, preventing the spark from entering filtration units and storage bins where violent explosions and fires can occur.

The system utilizes infrared detectors to sense burning embers or sparks transported through ductwork leading to a dust collector. Upon sensing a spark, it triggers an extinguishing device located downstream from the detectors, which produces a water spray to effectively extinguish the burning material. The system reacts in a fraction of a second, and the extinguishing device sprays just long enough to ensure suppression so that typically no downtime or clean-up is required. In applications where water is not an acceptable extinguishing agent, the Flamex system can also be programmed to activate other extinguishing agents, abort gates, diverter valves, or shut down equipment.

The Flamex system has been successfully used in a number of pellet manufacturing facilities across the U.S. and Canada. Call 336-299-2933; visit sparkdetection.com

Delivered Price Benchmark Offered

With Forest2Market’s Delivered Price Benchmark, companies producing energy from wood can reduce the price risk caused by the natural ups and downs of the wood fiber market. Just as they hedge their operational costs by tying adjustments to the Producer Price Index (PPI), they can use the benchmark to hedge the risk of changing feedstock prices.

“When you look at what we do and what wood bioenergy companies need to succeed, the fit is a natural one,” says Pete Stewart, industry expert and President/CEO of Forest2Market. “By indexing their power purchase agreements (PPAs) to changes in wood feedstock costs via Forest2Market’s benchmark, wood biopower producers can be sure their feedstock costs are in line with fair market prices.”

Indexing feedstock costs also increases the chances a biopower project will be financed. “These projects are just more bankable,” says Stewart. “Investors who are assured that both the power producer and the power purchaser are paying fair prices for feedstock are much more likely to back a project.”

Introduced in 2006, Forest2Market’s Delivered Price Benchmark service is the prevailing standard in the traditional forest products industry. In the U.S. South alone, the benchmark data reported to participating customers represents over 75% of the market, with 200 million tons of forest products annually, including wood fuel, sawmill residuals and chips. In the South, over 25 million tons of raw material move under supply agreements indexed to this price service annually.

The database contains 22 million actual sales records, on a load-by-load basis, and includes delivered cost components like freight and haul distance. Forest2Market’s Pacific Northwest Benchmark contains similar, though regionally specific, data.

Visit forest2market.com

Biomass Conversion Venture Formed

UOP LLC, a Honeywell company, has launched Envergent Technologies, LLC, a joint venture with Ensyn Corp., to offer technology and equipment to convert second-generation biomass into pyrolysis oil for power generation, heating fuel and for conversion into transportation fuels.

The new company will offer Ensyn’s Rapid Thermal Processing (RTP) technology to convert second-generation biomass like forest and agricultural residuals to pyrolysis oil. The joint venture will also accelerate research and development efforts to commercialize next-generation technology to refine the pyrolysis oil into transport fuels such as green gasoline, green diesel and green jet fuel.

Mark Reno has been named managing director of Envergent Technologies.

RTP is a rapid thermal process in which biomass such as wood chips or straw is rapidly heated at ambient pressure to generate high yields of a pourable, liquid pyrolysis oil, which can then be burned for energy in industrial burners and furnaces or converted to green electricity. Honeywell and Ensyn are working together on technology to further refine the pyrolysis oil into transportation fuels.

UOP, a leader in refining process technologies, has been active in renewable fuel technology, forming a separate Renewable Energy & Chemicals business in late 2006. Since then, UOP has commercialized the UOP/Eni Ecofining process to produce green diesel fuel from biological feedstocks and has also developed process technology to produce renewable jet fuel under a contract from the U.S. Defense Advanced Research Projects Agency. Call 847-391-2380; visit upo.com.

Biomass Drying Trailer Studied At U Of Idaho

Randy Hill, President of Advanced Trailer, announced that the University of Idaho has been selected as the recipient of a grant his company will fund to study the application of Advanced Trailer’s agricultural crop drying trailer for biomass.

Nearly two years ago Advanced Trailer began exploring the possibilities of using its drying trailer to remove moisture from woody mass by providing a trailer to the Herty Advanced Materials Development Center in Savannah, Ga.

The application will remove moisture from wood chips which are used as fuel for the University of Idaho’s steam boiler plant located at the campus in Moscow, Idaho. The results of this research will benefit biomass plants in other cities.

“The prior testing has shown that the trailer works and it does the job,” Hill said in announcing the grant. “But we were looking for a facility or institution that had an actual application where we could daily see the benefits of lowering moisture in biomass products used to fuel a plant. The University of Idaho was eager to put the trailer to work and we are excited about finding an educational institution with a direct and specific application.”

A video of Hill discussing the grant and its potential impact on the biomass industry can be found at the website, advancedtrailer.com, and at the Youtube link www.youtube.com/ userAdvancedTrailerTV.

In December, Advanced Trailer met with representatives at the University’s steam boiler plant. After touring the facility and seeing the similarities in handling wood chips compared to peanuts, plans were made to provide equipment to the school’s steam plant. Advanced Trailer is recognized as enhancing the peanut industry with its semi trailers that dry peanuts.

In late January, a trailer and dryer were transported from Advanced Trailer’s plant in Vienna, Ga. some 2,600 miles to Moscow, to begin the 12 month testing period. The grant will provide written research on lowering fuel (wood chips) cost while reducing carbon emissions by lowering the moisture content in woody mass products.

Horizontal Grinder Working In Thailand

West Salem Machinery’s model 5472BH Titan horizontal grinder is processing high volumes of stumps, land clearing debris and urban wood materials into biomass fuels for Gre Energy in Thailand.

The stationary electric grinder features dual electric drive motors and a fully proportional hydraulic feed system. The grinder features a 54 in. diameter by 72 in. rotor assembly. The 800 HP electric drive utilizes dual 400 HP motors. Machine capacity ranges from 40-100 tons per hour. Phone 800-722-3530; visit westsalem.com

Fiber Preparation For Renewable Fuels

West Salem Machinery announces the completion of a wood fiber preparation system for converting green chips, sawdust and shavings to pellet fuel. The system handles up to 100 green tons per hour of fiber, and includes pre-screening and shredding/ milling of material to an approximate 1⁄2 in. to 3⁄4 in. minus product size.

The system includes two WSM drag chain reclaims, which allow bulk loading and metered feeding of wood fibers, a belt conveyor with overhead self-cleaning permanent magnet, vibrating screen and WSM 4272S swing hammer shredder/hammermill. Pre-screening the incoming material provides increased thru-put with less energy consumption. Call 800-722-3530; visit westsalem.com

Heavy Duty Hog Is Cost-Efficient

Rawlings 4600 electric heavy duty portable horizontal wood grinder allows customers full grinding capabilities at lower operation costs, eliminating the high cost of diesel. The Rawlings HZX is a heavy duty wood hog that can process material of any length to the customers exact specifications. The simplicity of the Rawlings rugged design with the Super Hi Inertia rotor comes with an interchangeable Roc Wear Striker Bit system. All internal liners and sizing grates are bolt in eliminating high maintenance costs.

The Rawlings 4600 is protected by an Anvil Swing Away feature that allows metal and other damaging objects to drop through onto the outfeed conveyor before entering the grinding chamber. When shear pins are sheared a protection circuit shuts down the hog and conveyor to protect the machine.

The Rawlings Patented Multi Step Anvil serves as a primary breakdown, adding life to your sizing screen. All machines come with Rotary Temperature displays to allow the ability to constantly observe machines performance. A Centralized Auto lubrication center protects bearings at infeed and outfeed. Call 406-728-6182; visit wastewoodhogs.com

^ Top