Previous Page: [2]

Fiber Availability

Whatever the demand turns out to be, will there be enough wood fiber available to satisfy both established traditional plants and a wave of new energy facilities? The answer could be yes, no, or maybe, depending on who happens to be responding and what specific locale is being considered.

The so-called “Billion Ton Report,” released in 2005 by the Forest Service and Dept. of Energy, estimated that the country’s forest resources could potentially produce 368 million dry tons of wood biomass per year. Of this volume, after considering recovery issues, some 41 million dry tons could perhaps come from logging and other forest residues and possibly 28 million from urban wood residues (per year). For the record, one dry ton equals two green tons. With a mid-term horizon (2008-2030) instead of long-term (2004-2050), a new federal biomass study is nearing completion, according to the USFS’s Robert Perlack, a principal in the first study. Perlack indicates it should be more useful. “We want to disaggregate national resource potential and estimate feedstock supply curves by region, state and county for all major primary cropland and forestland resources at the farm gate or forest landing. These supply curves include costs for acquiring or accessing the resource and costs for its collection or harvesting and moving it to the field or forest edge.”

But it’s now generally accepted that forest residues, mill by-products and industrial and urban wood refuse—at least what can feasibly be recovered—will not likely be enough. That additional pellet plants, power/steam plants and ethanol facilities will tap into standing roundwood resources is a given. Going forward, this pulpwood fiber, which also serves as feedstock for OSB mills, could become increasingly scarce and more costly.

Division, Dollars, Definition

That prospect has led to budding division within the forest industry. Landowners, loggers and to a certain extent, sawmills, applaud new market opportunities accompanying the wood bioenergy market, yet pulp and paper manufacturers and some panel plants, OSB and MDF among them, are relatively cool to the idea. They see that market as disruptive in terms of competition, costs and control.

These differences have led to tension within some state forestry associations, whose membership primarily consists of forest products companies, landowners and loggers. For example, in Virginia in 2007, the pulp and paper lobby helped persuade the state general assembly to pass legislation that limits the amount of wood biomass eligible for the state’s Renewable Portfolio Standards credits (for generating electricity) to 1.5 million tons per year. Earlier this year, a Virginia lumber manufacturer succeeded in getting a local legislator to introduce a bill that would repeal the limit. The bill died in a subcommittee, thanks in no small part to fervent lobbying by pulp and paper interests. In another state, a large pulp and paper company reportedly pulled out of the forestry association after its membership officially endorsed the wood-to-energy movement. And in another, “paper” reportedly used its power to influence the outcome of an in-state forest resource availability study.

Needless to say, the pulp and paper community appears to be the most concerned over the rising wood energy tide. It fears that increased fiber demand will tax the sustainability of the forest resource and lead to declining fiber supplies and higher costs. Furthermore, pulp and paper companies complain about an unlevel playing field, citing renewable energy mandates and federal and state subsidies often given to companies that use wood for energy, particularly for power generation. For decades many pulp and paper plants have used bark, sawdust and a byproduct of the pulping process, black liquor, to generate all or most of their power needs. Some even generate excess power and sell it onto the grid.

But in recent months some pulp and paper manufacturers that produce kraft products have found a way to level the playing field by taking advantage of an alternative fuels tax credit traced to language in the 2005 highway bill, according to an article in the March 28th issue of The Washington Post (TWP). By mixing an insignificant amount of diesel fuel with black liquor and burning the material as an “alternative fuel” to generate heat and power, pulp and paper manufacturers appear to qualify for cash payments from the U.S. Treasury, the newspaper reported. It explained: “Because the tax credit is refundable, money-losing companies…qualify for direct payments from the Treasury, instead of offsets on taxes owed.”

Many pulp and paper firms have used black liquor as a fuel for decades but the key to qualifying for federal money is the addition of diesel fuel. The article noted that Verso Paper, which operates four mills, late last year received almost $30 million—only $7 million less than its then market capitalization. According to TWP, International Paper received $71.6 million in March for burning the fuel mixture at 15 of its plants for 30 days last fall. IP lost $452 million in the fourth quarter of 2008. Both Verso and IP stand to receive more millions. If they haven’t already, other companies are expected to file for the tax credit payments.

One published report noted the credit is available through the end of 2009 and indicated that an attempt could be made by Congress to keep it from flowing to the pulp and paper industry. Meanwhile, Canadian pulp and paper companies are upset with the development and are turning to the American news media in an attempt to get it overturned. In its April 16 edition, the Vancouver Sun credited Canadian pulp and paper sources with saying the subsidy can cut as much as 60% off the cost of chemical pulp in the U.S., opening a competitive gap that no producer in the northern hemisphere can match. “It also perverts the entire purpose of the tax credit, to decrease the use of fossil fuel,” said David Gandossi, Executive Vice President of Mercer International.

Last year IP executives commissioned an in-house study to analyze the “Effects of Renewable Energy Mandates on the Sustainability of Forests in the Southeastern U.S.” In their draft report, the two IP employees who conducted the study summarized: “This paper shows that renewable energy mandates, if not materially offset by other, more weakly positioned renewable resources in the Southeast, could lead to a substantial increase in regional biomass demand. This increase could change the character of the forest, compromise forest values and reduce the quantity of fiber available for use in forest products.”

Comments Bob Rummer, Project Leader, (USFS) Forest Operations Research, Auburn, Ala.: “I fully understand the concerns that existing forest industry has about the potential impacts of biofuel development. The potential market is huge. Suppose that someone invents the cellulose-to-oil process so that we can make a liquid fuel cheaper than we can from petroleum. What would limit the conversion of trees to fuel? That’s where the growing emphasis about sustainability comes in. For example, in the Energy Independence and Security Act, it includes a definition of renewable biomass that carefully excludes a lot of forest material from use to meet the Renewable Fuel Standard. The way that biomass will be limited is by legislatively restricting harvesting and conversion.”

Not all pulp and paper companies, including some doing business in northern New England, are wringing their hands over the prospect of competing with wood energy plants for fiber, according to Prentiss & Carlisle’s White, who reports that the consumers found themselves competing for “what we call white wood fiber for the first time last year.” The head-to-head situation lasted about six months before the pulpwood market took a left turn, taking demand with it. “They didn’t like having to do it, but 80 to 90% of the mills realized it was the way of the world,” says White, whose company supplies some 450,000 cords of logs and wood fiber each year to scores of mills in Maine alone. “Everybody is counting on biofuels and pellets, and we’re very excited about the markets,” he says. “But we’re very careful not to give up old friends for new ones at the drop of a hat. I’m not going to sell pulp and paper mills down the drain.” That sector in Maine, New Hampshire and Vermont consumes 16 million tons of pulpwood annually.

He vividly recalls the quick appearance of the short-lived wood energy phenomenon in the region 30 years ago but hints that this time it probably will endure and grow for a number of reasons, legislative mandates among them. Regarding resource supply concerns, he observes: “The short answer is at some points and in some places, there is a surplus of biomass. In other places, wood energy plants will compete with pulpwood markets.”

Plum Creek Timber Co., Inc., the nation’s largest and most geographically diverse corporate timberland owner—7.4 million acres in 19 states—apparently has wood fiber to spare and is reaching out to wood-to-energy companies. The company recently issued this statement: “Renewable energy markets are good for forestry and forestry is good for renewable energy markets. Plum Creek plans to serve as a catalyst in the development of the increasingly important renewable energy market, which will decrease our country’s dependence on imported oil. This is also a good business proposition for the company. Plum Creek’s core business is timber and we have the portfolio—which currently includes excess capacity—to serve both our long-standing pulp and paper customers and new bioenergy customers.”

Meanwhile, Congress continues its attempts at legislatively defining the term “renewable biomass” as it pertains to federal land, and some observers believe this definition could bleed into the private forest domain, or that the term “wood biomass” itself could be reinvented legislatively.

Both the American Loggers Council (ALC) and Forest Landowners Assn. (FLA) have weighed in on the debate. In recent weeks, the ALC board lobbied members of Congress to apply a very broad definition. Testifying last February before the Senate Committee on Energy and Natural Resources, Scott Jones, FLA Executive Vice President, said that a Renewable Electricity Standard (RES) will not result in an unsustainable forest resource and suggested that continued contraction in established forest products manufacturing could threaten the perpetuation of forestlands. “We do not have enough markets for the wood that we are growing; 2007 data show a 41% volume grown over removal in our country,” he said, asking: “Will family forest owners sell wood or will they sell real estate?” He urged the committee to be liberal in its definition of wood biomass. “No definition that harms capital investment in energy facilities or taints the siting of those facilities can benefit the future of America’s forestlands.”

Changing Forestry Face

All these developments are beginning to impact forestry and will alter its future course—more in some locales and regions than in others. Marshall Thomas, President of F&W Forestry Services, Inc., a 47-year-old management and consulting firm in Albany, Ga., recently addressed the region’s changing forestry face, describing it as “major, perhaps profound.” Writing in F&W’s Forestry Report newsletter, Thomas acknowledged announcements of new wood energy plants and their anticipated appetite for small trees. He pointed out that this is happening as the South’s forest is aging, creating “an interesting situation.” These aging trees were planted on a large scale from the mid-’80s to mid-’90s under the federal Conservation Reserve Program (CRP) and are now quickly transforming themselves into higher value sawtimber and poles.

Thomas pointed to an apparent stabilization of tree planting across the region at “about a million acres a year, less than half the rate during peak years of the CRP,” noting that the leveling off followed a pronounced 10-year post-CRP decline. Reduced planting can be attributed to at least three developments, according to Thomas: cutbacks in federal cost-sharing funds; a decision by private landowners to hold their sawtimber off the market due to low prices caused by poor demand (this slowdown in final harvests affects reforestation); and pulpwood-to-sawtimber management schemes adopted by new owners of timberland once owned by forest industry companies.

He went on to question the economic viability of recovering logging residues as feedstock for certain energy plants and the potentially adverse impact on soil quality if the practice proves to be economically sound.

Thomas is also concerned that some new wood energy plants announced in Georgia and Florida may have chosen sites based on less than realistic projections contained in the Southwide Forest Inventory Assessment (FIA) by the Forest Service. He pointed to two statewide F&W surveys revealing that the overwhelming volume of pine timber harvested in Georgia and Florida already comes from plantations rather than natural stands. Conducted in Georgia last year and in Florida in 2007, the surveys are sharply at odds with the most recent FIA projections, Thomas indicated.

Like others, Thomas welcomes new market opportunities for landowners and loggers. But he is concerned that the wood energy market could undermine established markets, further weakening them. He asked: “Are we about to go through another period where well-intentioned government subsidies will create some short-term high demand and prices, only to be followed by a collapse in demand if government policy changes?”

Less Waste, More Yield

Regions notwithstanding, common denominators seem to be a call for better stewardship of existing resources and a commitment to growing more fiber on less land.

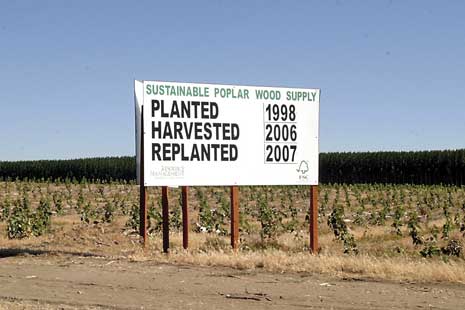

Sign tells the short rotation story at new-age hybrid poplar tree farm near Boardman, Ore.

Steve Kariainen, Resource Manager for Louisiana Pacific in Hayward, Wis., deplores the current timber volume going to waste on both private and public forests and the volume of forested acres that goes untreated (unmanaged). “We grow far more timber each year than we harvest; we could easily double the harvest of fiber if we actively managed all of our forest resources in a sustainable fashion. We cannot afford to continue to waste half of our forest’s potential if people want lumber, paper and fuel from trees,” he noted earlier this year.

To be sure, greater utilization is part of the solution, assuming private landowners could be motivated, and assuming that the U.S. Forest Service would (could) again place at least one foot on the commercial timber path. But the greater promise may well be in greater productivity. Biotechnology advances are accelerating plantation productivity in the U.S. and Canada (25% each) and abroad (as much as 300% in some countries), according to information on the web site of CellFor Inc., a leading supplier of high technology conifer seedlings. Furthermore, countries like Brazil are forging ahead with dedicated energy plantations. According Bob Flynn, a global forest industry authority for RISI, Brazil already leads the world with 3.7 million acres in forest energy plantations and is poised to displace the U.S. as the world’s second largest pulp exporter.

Another U.S. leader in advanced tree genetics is ArborGen, LLC, a provider of superior softwood seedlings that has developed several varieties of loblolly pine for planting in specific Southern zones and is attempting to develop a freeze-tolerant variety of eucalyptus that ideally will have reduced or modified lignin content—a big plus in the pulping process. With USDA permission, the company in late 2005 planted 500 seedlings of E. grandis on a 1.1 acre plot in southwest Alabama. Now believed to be 30 or more feet tall, the trees have withstood 17 degree temperatures. ArborGen wants its ultimate variety to withstand temperatures as low as 10 degrees. Prized around the world for its value as wood pulp feedstock, E. grandis offers “enormous potential” for the bioenergy market, particularly biorefineries, contends ArborGen. The company claims its variety has the potential to grow in four to seven year rotations, generally south of the Interstate 10 corridor, and yield 20 to 30 green tons per acre per year. The product is currently cycling through an extensive regulatory oversight process and will not be available for another two to three years.

Already out of the gate as an energy tree specialist is GreenWood Resources, Inc., a Portland, Ore.-based corporation that claims to be the nation’s leading hybrid poplar breeder and researcher and has emerged as a premier manager of advanced, short rotation, high-yield tree farms, including one in the Pacific Northwest owned by the GreenWood Tree Farm Fund (GTFF). Located in the Columbia River basin in both Oregon and Washington, the four tree farm properties comprise 35,000 acres and have exclusive access to GreenWood Resources’ elite plant material. The research center was originally founded in 1978 by Crown Zellerbach Corp. Some of the acreage was planted in the 1980s and is now yielding sawlogs that are processed at two GTFF sawmills. It claims yields of up to 20 green tons per acre per year.

But more importantly, GreenWood is using its breeding and research expertise and tree farm experience to promote poplar, along with willow and switchgrass, as feedstock for manufacturing cellulosic ethanol and other products. Earlier this year GTFF signed a letter of intent to supply poplar feedstock to ZeaChem, Inc.’s first cellulosic biorefinery (1.5 million gallons per year), which is planned for the Port of Morrow, near Boardman, Ore., not far from part of the tree farm. The companies hint they could partner in additional such facilities.

GreenWood owns research land in both Oregon and Mississippi and has created more than 40,000 varieties of hybrid poplar. It claims to have improved yields by more than 30% over the past 20 years. While it grows pulpwood and sawtimber, GreenWood is exploring ways to maximize productivity for biomass purposes, among them high-density plantings of 2, 200 per acre, managed on two- to five-year coppice rotations. Fertilization, irrigation and vegetation and pest control are part of the equation. It has used experimental machines that resemble combines to cut, shred and load the material into companion carriers, much like agricultural applications.

As significant as these steps are, they pale when compared with the potential productivity gains that may be possible with genetically engineered tree species and hybrids. Consider what has happened with corn seed. According to CellFor, in the 1930s yields of 20 bushels per acre were the norm; by the 1990s it was 100 bushels. Some 120 generations of improved seed have evolved since the ’30s. At best, trees are only in their third generation.

CellFor loblolly pine variety Q3802 thriving in Florida: age 4, height 22 feet. (Photo courtesy CellFor Inc.)

A federally regulated process, the genetic engineering of trees gives pause to some because it poses certain risks, according to authorities. But some nations appear to be headed this way and its potential is mind-boggling.

That may have led tree research scientists Roger Sedjo and D. Botkin, in a paper published in Environment, to suggest: “With forest growth and yield rates in the conservative range of what is currently possible for plantations in high-yield areas, all of the world’s timber production could potentially be produced on an area roughly five to 10% of the total forest today.”

That was nine years ago. Is it time the U.S. jumped on board? Or should it go slow?

There are multiple issues, points out Dr. Dale Greene, Professor at the Center for Forest Business at the University of Georgia. “Until energy prices get back to where they were and stay there, I’m not sure we’re ready to do what it will take to address our energy issues in a serious way. For example, eucalyptus is an exotic species and people now get nervous about plantations of native species. One of the biggest issues the U.S. Forest Service and state agencies face now is ‘invasive species,’ so these products would have to be sterile when planted, which is possible. I also wonder about the political and social acceptance of large-scale planting of exotics without a widespread energy emergency.”

Exotics aside, Greene also emphasizes that it is not simply a matter of genetics since to gain the full potential from this advanced material requires intensive, high capital management that may not be attractive to many small private owners. He asks, “Will enough private owners invest that much more and can the financial returns from biomass uses justify it? One wonders.”

Resources: Company Name, Company Name, Company Name